Leo Thomason

Executive Director & Instructor

Safety Notice – Mainstay CNG Fuel System Modules

If you own, operate or service CNG vehicles equipped with Mainstay Fuel Technologies fuel systems, there is a potential safety issue that requires your immediate attention.

Two product failures involving cylinder collar metal fatigue occurred in 2019 and 2020 with Quantum CNG fuel cylinders installed in Mainstay Fuel Technologies’ MSTAMA54 module. Manufacturing for this equipment occurred between 2013 and 2016. Details can be found in the referenced notice published by NGVAmerica January 4, 2022.

Mainstay also manufactured fuel modules using other CNG cylinder makes.

Any motor vehicle equipped with a Mainstay CNG module should undergo immediate cylinder inspection by a certified CNG fuel system inspector. This action is recommended regardless of timing since the last inspection.

Evidence of collar fatigue may not be visible to the naked eye unless the damage is severe and the CNG cylinder has already experienced a loss of containment. Therefore, the cylinder inspection process should include Modal Acoustic Emission (MAE) testing to detect damage at the base of the cylinder’s metal collar where it interfaces with the liner. Since MAE testing equipment is not part of routine fleet maintenance, it may be necessary to obtain services from a specialty third-party provider.

Introduction

Natural gas vehicle (NGV) owners and operators as well as NGV service and maintenance personnel should be aware of a potential safety issue with compressed natural gas (CNG) fuel modules manufactured by Mainstay Fuel Technologies. Known affected modules contained cylinders manufactured by Quantum Fuel Systems. Additional precautions and cylinder inspection are strongly encouraged as described below for motor vehicles in service and equipped with a Mainstay module. All recipients of this this notice are encouraged to share it openly and freely with others in the NGV industry to maximize its distribution.

Background

One of the many industry stewardship initiatives within NGVAmerica is to document, investigate, and report all potential safety and product defects associated with natural gas vehicles. As part of that ongoing effort, NGVAmerica began investigating two product failures that occurred within an eight-month period between July 2019 and March 2020. The failures involved CNG fuel modules manufactured by the former Mainstay Fuel Technologies; both affected modules contained cylinders manufactured by Quantum Fuel Systems. This safety notice is based on information provided by Quantum Fuel Systems and represents the facts and history relayed to NGVAmerica at the time of publication.

Within the time period specified above, metal fatigue was discovered on two CNG fuel containers in two separate Mainstay modules and two different vehicle applications. One of these containers suffered a loss of containment when the blind boss collar broke off. The exact cause of the metal fatigue is still unclear; possible causes include insufficient structural integrity of the CNG fuel module’s frame, physical impact damage to the module, and/or misalignment of the front and rear collar mounting blocks causing binding in the fuel container mounting scheme and improper loading between the respective slip collar and bushing.

Mainstay Company History

The CNG modules of concern were manufactured by Mainstay Fuel Technologies, which is no longer in business. Prior to going out of business, the manufacturer was located at 100 Hurricane Creek Rd. in Piedmont, SC. It is believed that all manufacturing occurred at this location, and therefore USA is the country of origin for all Mainstay modules. Manufacturer identification and phone number, (844) 332-3775, is typically listed on Mainstay modules, but this number is no longer in service.

Eco Vehicle Systems, located at 1274 IN-32 in Union City, Indiana, was involved in purchasing much of the IP and inventory during liquidation of Mainstay company assets. Attempts to locate Mainstay modules through Eco Vehicle Systems have been unsuccessful.

Identifying Equipment of Concern

The known incidents of metal fatigue involving Quantum CNG fuel containers installed in Mainstay Fuel Technologies’ modules occurred on the MSTAMA54 Mainstay module. Manufacturing for this equipment occurred between 2013 and 2016. The MSTAMA54 module is assembled with two (2) fuel containers of varying make.

Until an assessment is made that this issue is limited to the MSTAMA54 module, other variants of Mainstay modules also should be a concern from a safety perspective. NGVAmerica therefore encourages additional precautions for all Mainstay modules in operation. Regardless of year model or cylinder make, all personnel involved in the operation, service, and maintenance of a motor vehicle with a Mainstay module on board should seriously consider the inspection recommendation below.

Recommended Action

It is advised that any motor vehicle with a Mainstay CNG module on board undergo immediate cylinder inspection by a certified CNG fuel system inspector. This action is recommended regardless of timing since the last inspection.

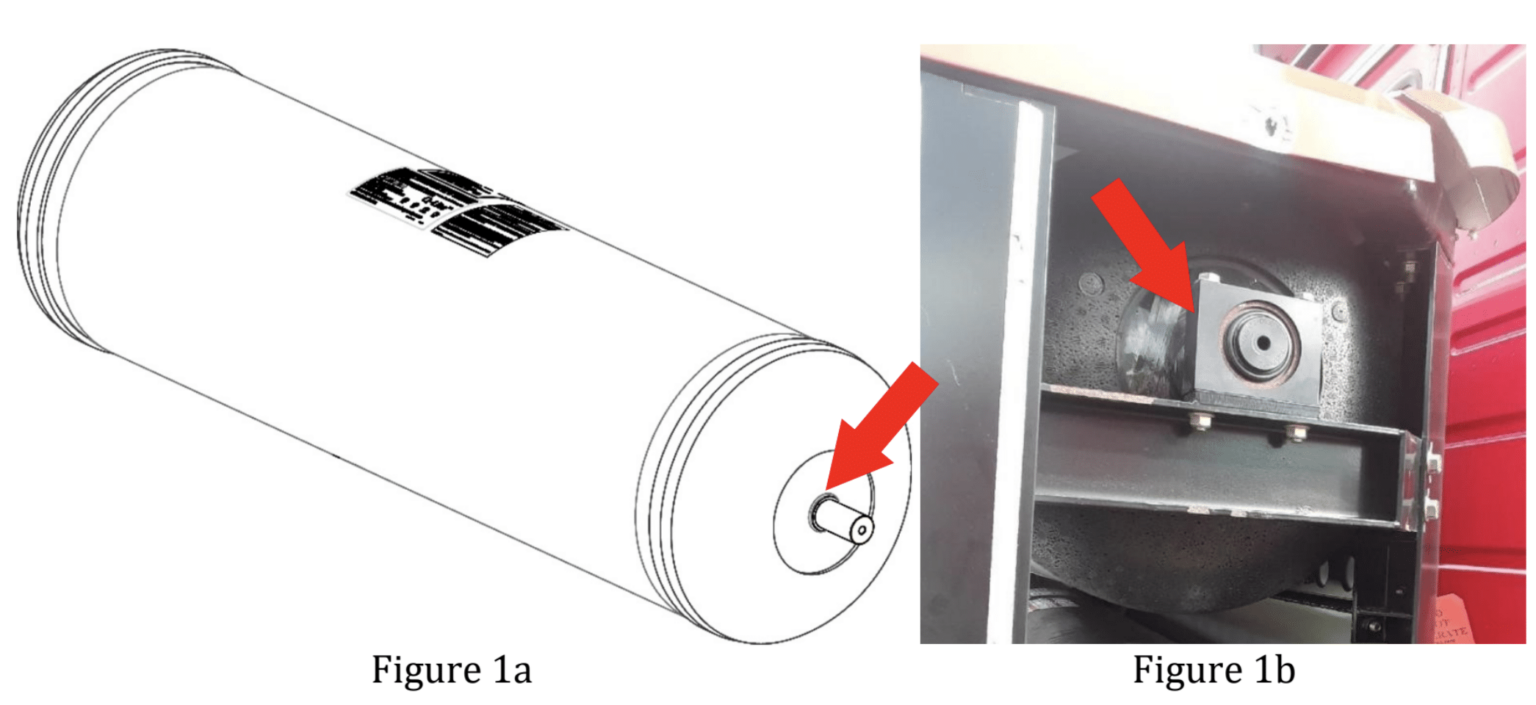

CNG fuel system inspectors should be advised that evidence of collar fatigue may not be visible to the naked eye unless the damage is severe and the CNG cylinder has already experienced a loss of containment. Lengthy evaluation of the failure mode in this case resulted in determination that special equipment is required to ensure CNG cylinder integrity. Therefore, this advised cylinder inspection process should include Modal Acoustic Emission (MAE) testing to detect damage at the base of the cylinder’s metal collar where it interfaces with the liner (see Figure 1). This testing and evaluation should provide the customer with a safe and reliable method to confirm integrity of the collar and the cylinder as a whole.

Figure 1a Figure 1b

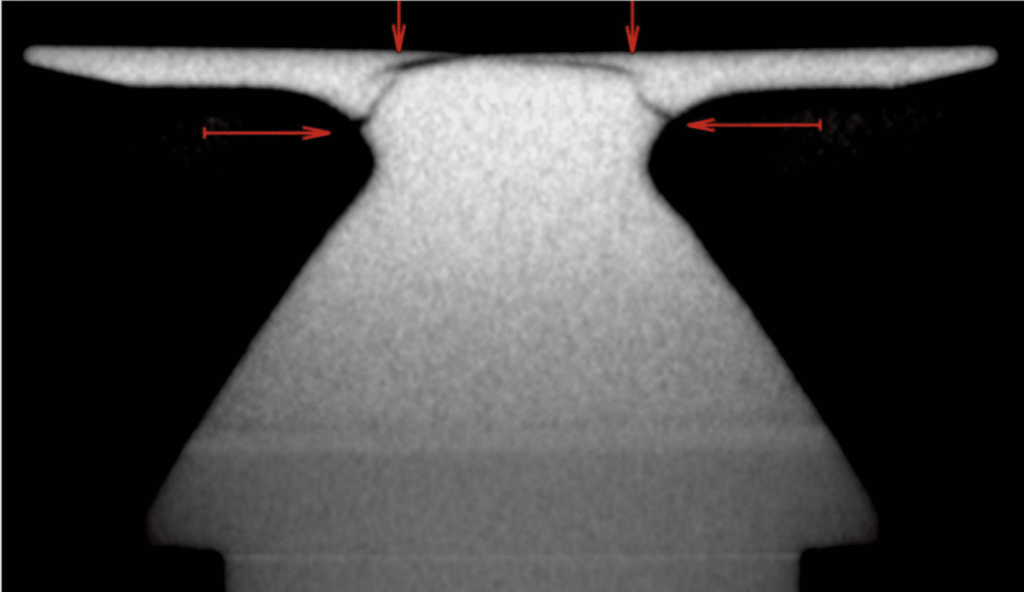

Identifying collar fatigue cracks at the base of the cylinder’s metal slip collar where it interfaces with the liner is critical for mitigation of this failure mode. MAE testing has been proven to be a reliable, nondestructive inspection method that allows owners of Mainstay modules to inspect the condition of their module systems and detect fatigue cracks such as those identified in test results (see Figure 2).

Figure 2

NOTE: CNG cylinder manufacturers should always be consulted as part of testing and analysis of results in special circumstances such as this. Mainstay modules are configured with different cylinder makes, and the respective manufacturer should be contacted before any final determination is made regarding evaluation, repair, or replacement.

Additional Guidance

For reference, the Federal Motor Vehicle Safety Standard (FMVSS) No. 304 specifies requirements for the integrity of compressed natural gas (CNG) motor vehicle fuel containers and the respective inspection intervals. NGV owners and operators should always consult their vehicle owner’s guide and/or the manufacturer for appropriate inspection procedures. If there is any sign of fuel container damage, the owner/operator should contact manufacturer of the vehicle or fuel container immediately for recommended actions.

Inspection guidance for CNG fuel containers is available from the following codes and standards documents:

1. FMVSS 304 – Compressed natural gas fuel container integrity – amended in 2000 2. CSA NGV 6.1 – Compressed natural gas (CNG) fuel storage and delivery systems for road vehicles – 2021 edition

3. CGA C-6.4 – Methods For External Visual Inspection Of Natural Gas Vehicle (NGV) And Hydrogen Gas Vehicle (HGV) Fuel Containers And Their Installations – Forth Edition

4. NFPA 52 – Vehicular Natural Gas Fuel Systems Code – 2019 edition

Summary

NGV owners and operators as well as NGV service and maintenance personnel need to be aware of a potential safety issue involving Mainstay CNG modules. The specific failure mode involves metal fatigue in the area of the fuel container’s blind boss collar, which can result in a loss of containment. NGVs equipped with a Mainstay module should be removed from service until the fuel containers have been tested to confirm integrity of the cylinders in the area of the blind boss collar. Multiple testing methods were evaluated to determine the effectiveness of detecting the presence of cracks in collars; MAE testing currently appears to be the safest and most reliable test method. For any additional guidance and assistance with arranging MAE testing or recommendations on alternative test methods, contact the specific manufacturer of the CNG fuel container.

NOTICES AND DISCLAIMER:

NGVAmerica has taken great effort to ensure the accuracy and reliability of the information contained in this document; however, this document is provided “as is” and neither NGVAmerica nor its employees or agents make any representation, warranty or guarantee in connection with this document, expressed or implied. NGVAmerica and its member companies disclaim liability for any personal injury, property or other damages of any nature whatsoever, whether special, indirect, consequential or compensatory, directly or indirectly resulting from the publication, use of, or reliance on this document. Nothing contained in this document should be viewed as an endorsement or disapproval of any particular service provider or products. The information contained in this document is not intended as legal advice. Questions regarding this document should be sent to: NGVAmerica, 400 N. Capitol St., N.W., Suite 450, Washington, D.C. 20001.