By Ted Amling, Sr. Project Engineer, Parker Hannifin Corporation, Tube Fittings Division

Effectively sealing fluids and gases at extreme temperatures is always a challenge, due either to the temperatures, chemical compatibility, limited connection options or space. Finding reliable connections for extreme cold, such as LNG systems, or extreme heat, such as fuel gas lines on combustion turbines, can be a challenge for engineers who often are not familiar with the options available for tube and pipe interconnect systems.

Effectively sealing fluids and gases at extreme temperatures is always a challenge, due either to the temperatures, chemical compatibility, limited connection options or space. Finding reliable connections for extreme cold, such as LNG systems, or extreme heat, such as fuel gas lines on combustion turbines, can be a challenge for engineers who often are not familiar with the options available for tube and pipe interconnect systems.

Sealing methods typically fall into two types for extreme temperatures. The first type is direct metal-to-metal sealing with no replaceable sealing element. This type includes compression fittings and 37° flare fittings. The second type uses replaceable gaskets to make the seal including ANSI flanges and its many variants, as well as the multitude of metal seal shapes to replace O-rings, such as c-seals.

There are limitations, however, to these two methods. Direct metal-to-metal sealing can be difficult to work with due to low tolerance for small scratches and imperfections. This sealing has limited reuse due to the required deformation of the sealing surfaces, and assembly procedures can be confusing to new users. Replaceable gasket sealing is an improvement over metal to metal sealing. However, traditional systems such as ANSI flanges require large space claims, while O-ring replacement metal seals can be cost prohibitive and typically have limited reuse potential.

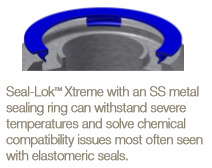

In response to these limitations, Parker’s Tube Fittings Division has developed a sealing system that extends the use of industry standard O-ring Face Seal Fittings (ORFS) to operate at extreme temperatures. Two new patented seals have been developed to work on both the ORFS tube end, as well as SAE J1926 stud ends. Parker’s Seal-Lok Xtreme™ is an SAE J1453 compliant ORFS fitting that uses patented metal sealing technology to provide -328°F to 1200°F sealing capability.

In response to these limitations, Parker’s Tube Fittings Division has developed a sealing system that extends the use of industry standard O-ring Face Seal Fittings (ORFS) to operate at extreme temperatures. Two new patented seals have been developed to work on both the ORFS tube end, as well as SAE J1926 stud ends. Parker’s Seal-Lok Xtreme™ is an SAE J1453 compliant ORFS fitting that uses patented metal sealing technology to provide -328°F to 1200°F sealing capability.

Operating temperatures for traditional ORFS fittings are limited by the seal material. Seal materials such as perfluoroelastomers (FFKM) can operate up to 600°F max, while very few elastomer seals can achieve more than -70°F. These materials can be very cost prohibitive and still do not extend the temperature range much past what more common FKM or HNBR seals can achieve. Metal sealing technology is really the only option for extreme temperatures, and the Seal-Lok Xtreme™ seals easily operate from -328°F to 1200°F, while providing a much broader chemical compatibility as a bonus. These seals are made from316 stainless steel and are coated with silver to promote sealing and prevent galling at high temperatures. Combined with 316SS fittings and tubes, this system provides a thermally stable connection with instrumentation-grade sealing available on industry standard ORFS fittings.

The Seal-Lok Xtreme™ system has been rigorously tested for both sealing performance as well as system robustness. Therefore, the Seal-Lok Xtreme™ system, when combined with Parker’s Parflange™ weldless flanging technology, brings all of the advantages of the ORFS fitting to markets and users previously unfamiliar with their many benefits.. This has made it one of the most popular fittings for high-pressure hydraulics on the market.

The Seal-Lok Xtreme™ system has been rigorously tested for both sealing performance as well as system robustness. Therefore, the Seal-Lok Xtreme™ system, when combined with Parker’s Parflange™ weldless flanging technology, brings all of the advantages of the ORFS fitting to markets and users previously unfamiliar with their many benefits.. This has made it one of the most popular fittings for high-pressure hydraulics on the market.

Some of the product benefits include:

- assembly to torque

- no damage from overtightening

- zero clearance for easier plumbing

- excellent vibration resistance

- unlimited reuses

- reduced assembly/ disassembly times

- positive seal retention

- enhanced anti-galling dry film lubricated nuts

- replaceable silver plated seals

- available in tube and hose sizes 1/4″ to 2″ (6 mm to 50 mm)

- AISI/SAE 316/316L stainless steel material (fittings and seals)

- working pressures up to 6000 psi

- meets requirements of ASME B31.1 and B31.3

Next time you are considering what product to use to connect your extreme temperature fluid or gas system, or if you are unhappy with the current choices on the market, consider Parker’s new patented Seal-Lok Xtreme™ ORFS fitting as an option.